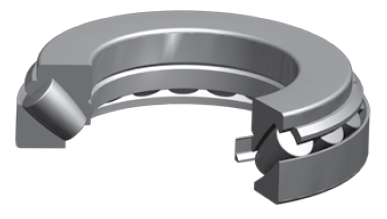

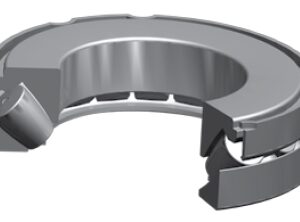

Specifications of TIMKEN Bearing 292/670EM

Specifications

| d – Bore |

670 mm |

| Bearing Type |

Thrust Spherical Roller Bearings – TSR |

| UPC Code |

87796066076 |

| Weight |

218.5 Kg481.8 lb |

Dimensions

| D – Outside Diameter |

900 mm35.433 in |

| d1 – Cone Outside Diameter |

865 mm34.06 in |

| D1 – Cup Bore |

773 mm30.43 in |

| E – Shoulder Diameter – Housing (Max) |

792 mm31.18 in |

| H – Shoulder Diameter – Shaft (Min) |

813 mm32.01 in |

| r – Fillet Radius |

5 mm0.197 in |

| S – Dimension |

363 mm14.29 in |

| T – Total Width |

140 mm5.512 in |

| T1 – Cage Position |

89.5 mm3.52 in |

| T2 – Groove Position |

44 mm1.73 in |

| T3 – Cup Width |

73 mm2.87 in |