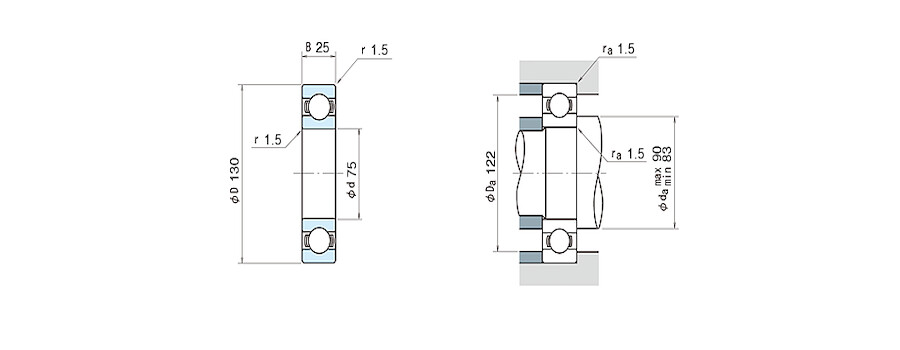

Specifications of NSK Bearing 6215 &

NSK Bearing 6215 & Single-Row Deep Groove Ball Bearings, NSK manufacture a full range of deep groove ball bearings. These bearings are the most common type and are used in a wide variety of applications.

Pressed Steel Cages Single-row deep groove ball bearings are the most common type of rolling bearings. Their use is very widespread.

In addition to open type bearings, these bearings often have steel shields or rubber seals installed on one or both sides and are prelubricated with grease. Also, snap rings are sometimes used on the periphery. As to cages, pressed steel ones are the most common.

For big deep groove ball bearings, machined brass cages are used. Machined cages are also used for high speed applications.

Deep groove ball bearings are versatile, self-retaining bearings. These bearings, which are of simple design, robust in operation and easy to maintain, are available in single row and double row designs and in open and sealed variants.

NSK Bearing 6215 & Single row deep groove ball bearings are the most frequently used type of rolling bearing. They are produced in numerous sizes and designs and are particularly economical. Due to their very low frictional torque, open bearings are suitable for high and very high speeds. Bearing designs with gap seals are suitable for high speeds.

NSK Bearing 6215 & Single row deep groove ball bearings are only suitable for compensating static misalignment to a very limited extent. As a result, the bearing positions must be well aligned.

Deep groove ball bearings are available in single row and double row designs. Single row bearings are particularly suitable where: high and very high speeds are required the bearing arrangement must be operated with very low friction very low running noise is required, without reducing the speed, load carrying capacity and operating life of the bearing (Generation C) high demands are made on the sealing of the bearing, without increasing heat generation or limiting the speed (Generation C) the bearing position is to be designed particularly economically