Ultra-low-friction linear ball slides are tiny parts that let machines move smoothly and easily over soft surfaces. Even though they look simple, they make a lot of tools work better by reducing vibrations, shaking, or sudden pulling. Because they reduce the stress on machine parts, they last longer and can be used for longer periods of time. These slides are used a lot in shops, labs, and work lines because they cut down on noise and make sure that parts move in a straight line. Because they fit into small spaces easily, they can be used with many different types of equipment. Importance of Smooth Low Friction Linear Ball Slides Important parts of a machine can move over smooth linear ball slides without making a lot of noise or needing a lot of force. This helps keep the workplace peaceful and productive. When slides move smoothly, tools vibrate less, which makes workers safer and more productive. When motion is smooth, parts are better protected from sudden shocks, especially in machines that move quickly. Smooth linear ball slides also save time because they make it possible for the machine to operate at a steady pace and get rid of small mistakes. Many companies choose linear ball slides for tasks that need delicate, low-drag movement. Key Points of Ultra-Low Friction Sliding is easy and comfortable for all-day comfort. Low drag makes the slide last longer. Less damage to motors and other parts of machines Calm movement that keeps things calm Works well in a lot of different machines and small spaces Helps parts move smoothly and evenly Vibrations, wear, and temperature that are not too strong The Best Linear Ball Slides for Daily Use THK LSP 2050 Linear Ball Slide The THK LSP 2050 is known for being very quiet, even when it’s under a lot of stress. Its gentle gliding motion keeps tools from going off course and makes any drag go away. Because it is so small, it can fit into tight spaces in machines easily. Also, it’s great for small labs and test settings because it keeps noise to a minimum. Its strong and steady motion makes machines work better and more smoothly. Great for: light tools, trim lines, and testing equipment. THK LSP 1390 Linear Ball Slide The THK LSP 1390 will give you a ride that is solid, soft, and comfortable. The small profile makes sure that parts move smoothly and consistently. Because it doesn’t make any noise and doesn’t create much drag, it is often used in testing tools, labs, and pick-and-place machines. It also works well in tight spaces where people need to be able to move around freely. This makes it a great choice for places where tools need to move quietly. Lab equipment and small vehicle setups are the best choices. THK LSP 1365 Linear Ball Slide The THK LSP 1365 gives you both soft and strong support as you move. It works well with machines that need stable guidance and can carry loads of medium size. This slide takes the pressure off of moving parts and keeps tools in line even after long shifts. Usually, devices that need to move smoothly and without stopping in one direction will use it. These work lines are perfect for operations with a medium load. Uses in Daily Work Laboratory tools that need to move slowly and steadily Pick-and-place systems with smooth motion Small blades that need to stay in place Look at devices that need to move quietly and perfectly. Strong robotic arms that need to be handled carefully Small assembly tools with straight lines of motion Inspection tools that move slowly and smoothly Pick the Right Slide Check the load to make sure the slide can hold the weight. Choose the stroke to make it go the distance you want it to. Check the size to make sure it fits in the machine. Choose the drag to keep the motion smooth. Choose how long you want the slide to last. Change the strength of the guide to keep the parts in line. You can change the volume to find a machine that is quiet. Quick Specs for Low Friction Linear Ball Slides Model Use Type Best Fit THK LSP 2050 Low drag Light tools THK LSP 1390 Slim fit Lab rigs THK LSP 1365 Strong guide Mid-load work Get Top Ultra-Low Friction Ball Slides NOKS INTERNATIONAL TRADE GROUP LIMITED is the most trusted place to buy linear ball slides from. They offer strong and reliable products that work well for daily use. They also provide fast help and clear support so you can feel confident when buying from them. You buy the best products from them with the top durability. FAQs What makes linear ball slides move so smoothly? They use low-drag parts that reduce friction and help parts move easily. Are they simple to install? Yes, they fit well in many small and mid-sized machines. Do they last a long time? Yes, the low drag helps them stay in good shape for a long time. Can they be used in robot arms? Yes, they help robot arms move quietly and smoothly. Where can I buy them? From NOKS INTERNATIONAL TRADE GROUP LIMITED, a trusted seller of high-quality parts.

Industrial micro-finish wear sleeves make machines last longer by giving shafts a smooth, clean surface. These small parts are very important for keeping seals in good shape and stopping leaks. Their machines work well and safely, even when they are carrying heavy loads or running for long periods of time. These sleeves can help keep all the parts clean, save money, and cut down on the need for repairs. You can find them in stores, repair shops, and factories, where they are used for strong and simple parts. Sleeves Help Machines Work Better in Many Steps Wear sleeves with a micro-finish that fit tightly on the shaft. This gives the seal a clean, smooth surface to slide over. There are no leaks because the oil stays where it should be, inside the part. They don’t need a lot of tools or time to set them up. This lets experts fix broken shafts without having to replace the whole thing. This helps us save time, money, and energy. These sleeves give you extra protection from heat, dust, and movement. Workers Choose Wear Sleeves for Smoothness These sleeves can help you fix a lot of shaft problems. They make the machine more stable, easier to clean, and safer to use. Workers like them because they are comfortable, last a long time, and make the machine run longer. Because they work with many different kinds of seals, they can be used in many different ways. Strong Sleeves From the Leading Brand NOKS INTERNATIONAL TRADE GROUP LIMITED sells micro-finish wear sleeves that last a long time and work very well. These sleeves let you seal things up tightly, move fluids around, and use machines without any risk. SKF 99859 Wear Sleeve The SKF 99859 wear sleeve can quickly fix a worn shaft by making a new, smooth surface for seals to work on. Because of this, the equipment should work normally, without any leaks or damage that wasn’t expected. Because it is made of strong steel, it can handle high temperatures, oil, and fast rotation. It is easy to install and keeps seals safe from heat and debris. Key Data d1: 139.7 mm D: 150.83 mm b: 25.4 mm bB1: 20.65 mm B: 31.75 mm r: 3.18 mm T: 0.25 mm Mass: 0.302 kg How the SKF 99859 Sleeve Helps This sleeve makes a tight and clean seal. It keeps oil from leaking out, which could hurt parts. Using it is good for all kinds of equipment that runs for long periods of time, like big motors, strong pumps, and heavy-duty tools. This is helpful for people who want a simple, cheap fix that doesn’t involve changing the shaft. SKF 99875 Wear Sleeve The SKF 99875 wear sleeve can handle long periods of use and quick acceleration. It makes the seal’s surface smooth, so it can move smoothly without hurting the shaft. It works well and quickly fixes a lot of shaft problems, even when it’s hot, dusty, or greasy. Key Data d1: 175.01 mm D: 83.95 mm b: 26.01 mm b1: 22.0 mm B: 33.35 mm r: 3.18 mm t: 0.25 mm Mass: 0.0299 kg How the SKF 99875 Sleeve Helps This sleeve will keep the seal from wearing out too quickly and will stop leaks. It is strong even though it is thin and light. It keeps a firm hold on the shaft and works well over time. This sleeve is a lifesaver for a lot of tools and machines in logistics, workshops, and factories. SKF 99351 Wear Sleeve The SKF 99351 wear sleeve can fit shafts that are between 189.92 and 190.07 mm wide. It repairs damaged areas and gives seals a new surface to work on. This stops machines from losing oil and keeps them running smoothly. Iron and steel don’t get damaged by heat, dust, or pressure. Key Data Shaft range: 189.92–190.07 mm Mass: 0.155 kg How the SKF 99351 Sleeve Helps This sleeve makes it easy to fix wear on shafts, and it also protects them for a long time. It makes things cooler, stops leaks, and stops damage. It can be used in many different devices, such as engines and big pumps. It works with sleeves for repairing bearings, seals, and shafts. Pick NOKS INTERNATIONAL TRADE GROUP LIMITED What Makes NOKS a Good Choice NOKS INTERNATIONAL TRADE GROUP LIMITED sells a lot of different types of long-lasting sleeves. Their sleeves can fit on a wide range of shafts, loads, and seals. They are easy to use, safe, and very useful for fixing things. Their products make machines work better and need less maintenance. What They Offer They have a lot of sleeves in stock, including bearing shaft wear sleeves, seal wear sleeves, and sleeves for shafts. A strong structure, easy maintenance, and a focus on safe work are all important. The staff there offers quick answers, simple explanations, and easy ways to pay. FAQs What do wear sleeves do? Wear sleeves, repair worn shafts, and provide seals with a smooth surface to ensure smooth movement. Do they fit many machines? Yes. Many wear sleeves fit pumps, motors, tools, engines, and more. Are they easy to install? Yes. Most sleeves can be put on quickly and require no special tools. Why choose SKF sleeves? SKF sleeves are strong, smooth, and made for extended use. Where can I buy these sleeves? You can buy them from NOKS INTERNATIONAL TRADE GROUP LIMITED in many sizes and types.

Wear sleeves that are small, light, and easy to put on are made to slide over worn or rough spots on older shafts. By wrapping the shaft in a new layer of soft skin, these sleeves change its shape and make it look like new. This simple action helps to quickly stop leaks because the seal is now resting on a clean surface. These sleeves help cut down on repair time and costs because they don’t need to replace the shaft. Each sleeve is small, strong, and easy to put on. You only need a few simple tools to get it into place. The machine can run safely and continuously for a long time after it is attached to the shaft. These sleeves will make the job easier, no matter how big or small it is. Vital Reasons to Use Wear Sleeves Seal wear sleeves are great when the shaft has small dents, cuts, or rough spots that let water in. These sleeves are easy to put on and stay flat, which protects the seal. They keep things in order at work and stop oil from leaking. They are used every day for many things, like farm tools, car parts, and industrial equipment. Also, they help keep the seal from getting too hot by making sure it can move freely on a flat surface. Two of its main jobs are to keep the seal lip safe from sharp edges and to make sure the seal stays strong for hours of use. The machine runs more quietly and safely with each sleeve. Key Benefits: How Seal Sleeve Parts Help A seal sleeve gives the seal lip a smooth, cushioned surface to slide over. Because of this, oil can stay inside and stop wear and tear from happening too soon. These sleeves are very strong for long tasks, even though they are small, light, and simple. They make it easier for the machine to work on both light and heavy jobs. When the seal seat is clean, machines last longer and need fewer repairs. With a sealed sleeve, the shaft stays stable, calm, and much safer. Important Functions: Exact Time to Use a Shaft Sleeve A shaft sleeve is needed when a shaft shows clear signs of damage. If the shaft has pits, dents, cuts, or worn areas on its surface, it is no longer in perfect condition. Instead of having to replace the whole thing, putting this thin sleeve on the shaft will give it a new, clean face. Not only does it fit tightly, but it also stays in place and helps you put the seal in the right place. The machine can now stay quiet and not leak. It is often used in tools that need safe and smooth shaft areas. Signs You Need One: Wear Sleeve for Oil Seals in Daily Work Wear Sleeve for oil seals prevents damage to the seal lip from sharp shaft markings. It helps the seal last longer. It will work great no matter how hot or humid it is. It protects the surface from dirt and makes it level so the seal can stick. This makes sure that the equipment works well, quietly, and safely. This sleeve will help the seal work better and last longer. Good For: Select a Shaft Repair Sleeve A repair sleeve can help you fix a broken shaft quickly and cheaply. You don’t have to take the shaft out or replace it. You’ll be ready to go in no time if you put on this sleeve. It is made to last through everyday use. The shaft stays solid, straight, and safe even when the machine is fully loaded. We save time, money, and energy by doing this. Main Benefits: Strong Use of Shaft Wear Sleeve A shaft wear sleeve gives the seal a smooth, clean, and even surface to rest on. This makes the seal hold on better and stop leaks. It can handle a lot of heat, heavy loads, and brute force. It’s made for tough machines that work all the time. It helps keep gear sets, pumps, and fans stable and safe. The sleeve keeps the workflow going smoothly and cuts down on breaks at work. Great for: The Power of a Thin-Walled Sleeve A thin-walled sleeve is both light and slim, and it supports the seal without adding bulk. It won’t make the shaft much bigger. It fits well and doesn’t need any work to clean. It will be loved by minimalists. It helps the machine run quietly and efficiently. Because it is light, it can be set up quickly while still giving the seal a lot of support. Why Pick It: When to Choose a Heavy Industrial Wear Sleeve Heavy Industrial Wear Sleeves are needed for big plants, strong tools, and rough ground. It can handle extreme temperatures, hard hits, dust, and a lot of work. It helps the seal stay safe when it has to do hard work. The equipment won’t be down for long, and it lasts a long time. Best Fields: Best Quality Quick-Fit Wear Sleeves SKF 99847 Wear Sleeves The SKF 99847 sleeve keeps the shaft’s seal safe and clean. It has a lot of uses and is simple to put on. The seal slides on easily and stays put because the surface is smooth. It will work well for light to medium work if the markings on the shaft are small. It makes sure that the shaft won’t move around or leak. Important points: Why You Should Choose It: Great for shafts that don’t need a seal path that has been heavily worn cleaned up. SKF 99850 Wear Sleeves SKF 99850 sleeves are made to handle very strong forces. It can handle heat, force, and rough ground. It gives the seal a stable, flat, and clean surface to rest on. Made of strong steel, it keeps the seal safe and stable even during tough jobs. Important points: Why You Should Use It: It’s great for gear units, … Read More “Quick-Fit Wear Sleeves for Leak-Free Seal Performance” »

Everyday tools need to work smoothly. A tool that moves easily cuts down on heat growth, scraping, and noise pollution. This is why linear ball slides can be used in so many different ways. The balls follow real travel lines and don’t get in the way. The tool stays steady even when the loads change because it glides smoothly. Don’t jump. Smooth changes. It seems like every job is easy and safe. The slide will stay in place no matter how fast or slow you go. This is useful in homes, garages, stores, and labs. People of all ages might feel empowered by how easy it is to follow each step. Key Role of Ball Blocks A linear motion is needed for easy transportation. You absolutely need a ball-bearing sliding block. It uses a gentle roll to hold the weight and lets the part move in a straight line. It makes the force less strong. Lessens drag. It holds the rail in place. The block makes sure that the motion is safe and solid. It also holds the weight of your tool without leaning. The little balls spread the force evenly. They maintain the block’s alignment. It is less likely to twist with their help. This keeps everything in order, which makes the process seem less scary. Low Wear and Long Life These linear ball slides have the little balls neatly lined up in a row. They roll in a soft and light way. This gentle roll can help things last longer. It makes your slide last longer while keeping it looking new and strong. You can use it for a long time with little upkeep. Parts are not ground or burned. The rail is still flat. There are no obstacles in the way of the path. The slide stays strong even after many uses. The balls stay strong and flexible. The rail doesn’t bend. The mobility stays almost the same for a long time. Very Little Force Needed You don’t need much force to move a linear ball slide that has ball bearings. This means we use less energy. It keeps your hands from getting stressed. You can easily move the part, no matter how heavy it is, with just a little pressure. You don’t have to pull the cargo; it can slide down the slide. This will be a very useful tool if you have to move parts around a lot or work in tight spaces. It relaxes the hands and makes the whole day easier to get through. Vital Advantages of Linear Ball Slides 1. Clean Work in Small Spaces When doing delicate work or working in tight spaces, you need to be able to move your hands quickly and easily. A small linear ball bearing sliding block is perfect for this job. It lets you glide smoothly even in the most inconvenient places. It stops sliding and keeps rubbing from happening. It lets you work calmly and carefully in a small space. You are in full control. Moves are slow and purposeful. This will help you keep your tool stable when you’re working with small, fragile parts. 2. Steady Moves for Test Labs For lab work, you need to be reliable and calm. The linear slide of a ball screw makes the action smooth and steady. Test instruments are safe and stable. It lets you control small changes with great accuracy. That way, everything stays neat. Holds delicate parts in place. It also makes sure that the test data stays correct. Because it always takes the same route, the tests are still fair, repeatable, and reliable. 3. Light Touch for Fine Parts A gentle glide is needed to work with small, fragile parts. The linear motion of a ball’s slide gives it a soft feel. It protects all of the parts. It keeps them in place very well. It doesn’t matter how fast or slowly you move the instrument; it stays still. Put fragile things inside the soft roll. This is good for tools used in arts and crafts and small mechanical jobs. 4. Strong Hold for Heavy Loads Heavy tools need strong bases. This strength comes from the way the broad linear ball bearing slides are set up. The load is held safely. I promise you, it stays still. It fixes the angle. It gets rid of droop. Because the weight is spread out, the load can slide easily along the wide rail. You can use even the biggest tools on it without worrying about them getting stuck. 5. Quiet Action for Work Rooms Calm tools bring peace. A sealed linear ball slide keeps dirt out and rolls smoothly. There is less noise and vibration as a result. The peace at work is better. The slide moves along in a slightly musical way. This is helpful in places where complete silence is needed, like labs or offices. 6. Easy Fit in Many Tools These slides come in different sizes. They could have a lot of different tools, like those used in the lab, around the house, in the workshop, and even CNC machines. It’s easy to set them up. Choose the right size for the job. They can handle both big and small installations just as well. Top-Grade Linear Ball Slides THK LSP 25100 Linear Ball Slide This long slide makes it easy to hold on to wide things. The THK LSP 25100 Linear Ball Slide gives you tight control. The roll stays soft. It has a strong rail. It tells you to stay tight. It works great for instruments that are medium to large in size. It moves easily and steadily, so it can handle a good amount of weight. THK LSP 20100 Linear Ball Slide This slide will fit a medium-sized tool. The LSP 20100 linear ball slide from THK moves smoothly and neatly. It works well with tools that need to move fluidly. It keeps the weight secure and reduces drag. It gives safe, guided travel while doing many normal things. … Read More “Precision Linear Ball Slides for Smooth Motion and Stability” »

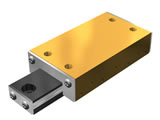

Cam followers? You see them in all sorts of machines these days. Though they seem tiny, they’re super tough! They keep things running like clockwork and can handle seriously heavy weights without a sweat. From your car to factory equipment to robots, cam followers are quietly working away to keep everything humming. If you get a premium Cam Follower, you’re investing in parts that last longer, run better, and can be trusted to do their job. Here at NOKS INTERNATIONAL TRADE GROUP LIMITED, we give you heavy-duty cam followers and other bearings that our customers around the world love. Our parts come straight from brands you already rely on, things like SKF, FAG, INA, NSK, NTN, KOYO, IKO, TIMKEN, THK, and more. Premium Cam Follower That Just Works IKO cam followers, think of these like specialised roller bearings, making sure machine motion is spot-on. They’re built to manage crazy loads and keep on trucking without wearing down early. These are the parts you’ll find in machine tools, robots, consumer electronics, and even office equipment. What’s so great about IKO cam followers? They are all about being tough and being made with care. The outer ring is made of stuff that withstands a beating. Plus, it has a polished coating that keeps rust at bay. Inside, there are little needle rollers doing the heavy lifting and allowing smooth movement. Each cam follower has between 15 and 40 of these rollers inside, and they come in sizes to fit tons of different machines. The rollers are made so they spread weight without producing extra friction. That’s made from extra-strong steel. The threads are exact, and it’s straight as an arrow. That makes it simple to fit right and keeps things moving efficiently. What Are They, and How Do They Work? Industrial roller followers are a kind of bearing with their own purpose. They follow the movements of a cam. A cam is a machine piece that moves around in a specific way. The cam follower goes along the cam’s shape, turning spinning into straight-line movement. This lets machines move in definite ways, while cutting down on friction and preventing wear. Inside, rollers or needles help avoid friction. These rollers make sure the weight is evenly distributed. This keeps damage low and machines working. Why Choose Premium Cam Followers for Your Machines Your machines are only as high-load cam follower components as you put inside them. If you pick the cheap stuff for cam followers, you may see things wearing down fast, breaking down often, or simply underperforming. But decent cam followers? They’re made to take on big weights and keep friction low. If you get premium Cam Followers, your machines will sing. They’ll keep everything moving easily and steadily. They will last; less cash spent on replacements and fixes. Precision cam follower bearings are built using strict standards; you can rely on them in rough places like factories, construction sites, and auto shops. Key Features of Premium Cam Followers Top-tier cam followers have great stuff happening on the inside. They’re compact but mighty, great for tight spots without losing the support you need. They also have smooth finishes that keep friction and heat down. This means machines work well and stay quieter. And lasting power is key. Awesome cam followers use tough steel or coatings to stop wear, rust, and corrosion. Some are sealed off to block dust and dirt, which helps them last longer. Built well and checked closely, these linear motion cam followers keep performing, even when the load gets heavy. Different Types for Different Kinds of Work There are different kinds of cam followers, depending on your application. Common ones are stud-type and yoke-type. Stud-type ones have a built-in stud so that you can screw them onto a surface. Yoke types have two arms on the side and are held on with bolts. Some cam followers handle really big weights; others are made for speed. Needle roller cam followers have small rollers inside to support weight in a small space. You can get a premium Cam Follower made of stuff like stainless steel or ceramic for tougher conditions. The kind you pick greatly impacts how well your machines function and how long they’re in service. Benefits of Using Heavy-Load Cam Followers in Industry Heavy-load cam followers can take on more weight than typical ones. That makes them good for factories using machines that lift, push, or move heavy things. When you pick these tough cam followers, you reduce wear on other parts because they share the weight. These premium Cam Followers also make machines work better. They roll without a hitch, so less energy is used. This helps with saving money and producing more product. Industries like cars, packaging, robotics, and building sites use heavy-load cam followers to keep things running well and safely. Materials and Build Quality That Ensure Long Service Life What cam followers are made of is extremely important. Solid ones mostly use good-quality steel. But stainless steel, ceramic, or coated metals are also picked for durability. These materials stand up to rust, corrosion, and wear, even when situations get intense. Building is key, too. Premium Cam Followers are designed and checked for being accurate, supporting weight, and smooth movement. Careful work on the machining results in easy roller motion without friction. When you combine all of these, you get automated machinery cam followers that take a beating and do things right. Common Applications of Cam Followers in Machinery They’re everywhere. You’ll find them in vehicles, robots, factories, and heavy equipment. Check this out: Almost any place where smooth motion and heavy load support are important, cam followers are likely involved. How to Pick the Right Cam Follower To pick the premium Cam Follower, you need to know what your machine needs. Decide on the load. If you’re moving heavy stuff, get a heavy-duty cam follower. Also, consider speed and how things move. Quick jobs need cam followers that spin easily and have little friction. … Read More “Buy Premium Cam Followers–Smooth Motion & Heavy Load Support” »

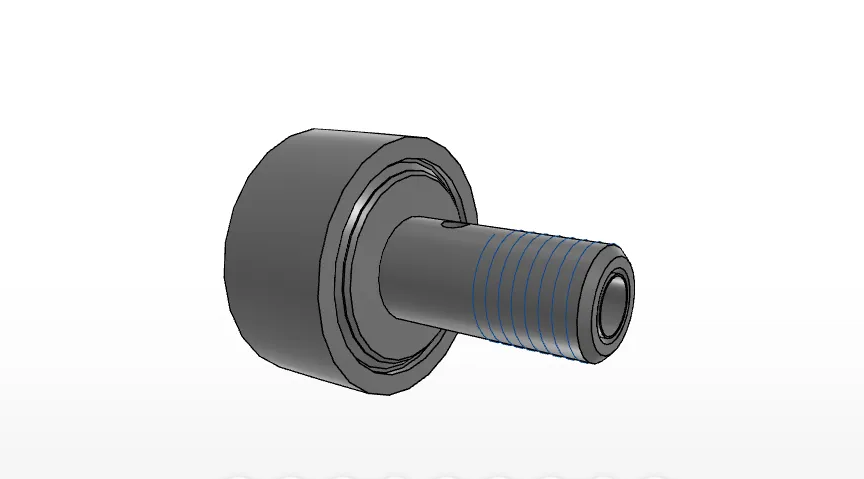

Want your machines to run without a hitch? You want parts that can take some punishment. Bearings are key—they keep everything moving, right? There are quite a few brands out there, but IKO makes amazing IKO Needle Roller Bearings. These things are tough and perfect for machines that are always on the go. Pick IKO, and you’re getting parts that will last and get the job done right. IKO Needle Roller Bearings: Ready for anything! IKO needle roller bearings shine when space is tight. They use needle-shaped rollers to manage seriously heavy stuff without hogging room. They can handle way more weight than regular ball bearings, so your machines will run great, even if space is limited. You’ll spot these IKO precision needle bearings everywhere—like in cars, motorcycles, printers, factory robots, and those huge construction trucks. They’re made tough, so they’re awesome when you need major power but don’t have a lot of room. IKO really sweats the small stuff when making each bearing. They keep them small, pack in as many rollers as they can, and use awesome cage materials, like strong polyamide, cold-rolled steel, and machined brass. These cages help the bearings do their work when things get fast, hot, or just plain rough. Plus, the finishes and covers give them extra life. To keep these going strong, IKO uses steel to make sure these industrial needle roller components can handle a pounding. You can even find ceramic or rust-proof versions. The rings and raceways even get special coatings, like black oxide or DLC coating, for extra protection. Why Go With IKO Needle Roller Bearings? Lots of industries go with IKO needle roller bearings because they’re strong and dependable. These bearings are packed with tiny rollers, so they can deal with those super-heavy loads without taking up too much space. It’s a great setup, just right when machines need to be tough but are stuck in tight spots. IKO makes sure these high load capacity needle bearings really hold up. If your machine keeps running, it’ll last longer and perform better. Many engineers trust IKO for factory equipment, workshop tools, and big machines. Key Features of Premium IKO Bearings IKO needle roller bearings are seriously impressive. One amazing thing is how compact they are. They’re small but can still handle big loads. This means they’re great for machines that need to stay strong, even when doing really hard work. They don’t cause much friction. The rollers glide smoothly, so the bearing doesn’t get too hot. That means machines run quietly and smoothly. IKO uses top-notch steel and checks everything carefully, so each bearing is great. Because of this, the bearings last a long while, do what they’re supposed to, and are safe. Wide Range of IKO Needle Roller Bearing Models Available IKO has all sorts of needle roller bearings, so you can find exactly what your equipment needs. Some bearings have cages, and some don’t. Some are good for going fast, and some are for holding lots of weight. You can even find compact design roller bearings that squeeze into spots other bearings can’t. That lets engineers grab just what they need. Whether you’re dealing with cars, robots, packaging, or heavy machines, IKO has got your back. With choices like these, you can get better action and have your machines running longer. Precision Engineering for Smooth and Reliable Performance IKO is all about making sure everything is spot-on. Each bearing is built with machines that shape each roller carefully, so the bearing works smoothly, without any shaking or noise. Machines with IKO bearings just work, every time. Smooth performance means things don’t wear out as fast. When parts move without trouble, they last, and that helps companies save on repairs. With IKO, you know you’re getting performance you can depend on, even when things get super tough. High Load Capacity and Long Service Life IKO needle roller bearings are strong because they spread the weight evenly across lots of small rollers. These rollers share the load, so the bearing doesn’t give out. This setup lets the bearing handle heavy loads without a problem. IKO bearing applications You’ll see places with IKO needle roller bearings all over the place because they do the job on all kinds of machines. In cars, these bearings help engines, gearboxes, and steering systems run smoothly. For robots they support joints and arms that need to move nicely. Factories also use IKO bearings in conveyor belts, packaging machines, cutters, and printing presses. Big industries, like construction and mining, use these bearings for cranes, loaders, and drilling tools. Quality Assurance and International Standards Compliance IKO has tough rules when making needle roller bearings. Each bearing is checked to make sure it’s strong and correct. IKO uses quality control systems to test size, hardness, speed, and how well the bearings handle loads. These checks make sure the bearings hit the mark and are safe in any shop. When you pick an IKO bearing, it’s been checked, which lets engineers know the machine will run as it should. Good Prices and Choices for Big Orders Even though IKO Nippon Thompson bearings are top-notch, they’re priced well. Businesses save even more when they buy a bunch. Many suppliers have deals for big orders, making it easy for companies to buy in bulk. Industries that use tons of bearings each month can save by buying a lot at once. This helps keep the cost of running machines down and makes planning easy. Plus, you won’t have to change out IKO bearings as often because they last so long. Fast Shipping and Safe Packing Industries need bearings fast. If a machine is down, it can cause businesses trouble. Good suppliers give delivery you can count on. IKO bearings are packed in strong boxes so they don’t get banged up on the way. Good packing keeps the rollers and rings clean and safe from dirt. Fast delivery and safe packing mean you get your bearings, ready to put in your … Read More “Premium IKO Needle Roller Bearings – Shop Quality Bearings” »

This Linear Ball Slide lets things slide slowly, softly, and calmly now that it has even more precise steps and longer lines of smooth flow. The technology uses small, quick balls that easily glide along set paths, making travel light and safe. The roll route moves smoothly and brightly. The whole glide, from the first push to the last stop, is very smooth. I feel safe and confident in the work. The part stays in place for a few days. The part stays clean no matter how hard the work is. It doesn’t stress you out very much if you use it for a long time. It gives clear, simple instructions that are also kind. Good for a lot of different instruments, big and small, that need slow, steady movements. Why It Feels So Smooth The small ball roll lines on this Linear Ball Slide keep each roll snug and tight. They go down a path that is strong but not too rough. The roll and the slide don’t move or shake. The motion doesn’t pull or drag. The form and framing make the action more direct and clear. The strong frame keeps the line straight. With every stroke, the glide stays the same. A calm motion creates a calm place to work. The sound is soft. Less shaking. Every piece of work brings you more peace. Where You Can Use It You can use the slide in small spaces with only a few tools. It works well in big tool areas with wide frames. Some lab tools can use it to test parts that are very sensitive. Tools that cut or shape things in a shop can use it. It can be used for testing that needs straight lines and slow speeds. It is helpful for long periods of time when you need move lines that are smooth, clean, and steady. It keeps duties organised and works in a lot of different fields. Key Good Points Top THK Linear Ball Slides THK LS 25150 Linear Ball Slide This LS 25150 part has a long rail that makes it easier to glide and reach. A smooth push makes the movement go farther. This roll stays flexible and clear. Everything in the body is strong and solid. The slide is still clear, even after a long time. It moves quietly and smoothly, which makes it perfect for equipment that needs those kinds of lines. It can help all kinds of labs, workshops, and craft supplies. THK LS 1077 Linear Ball Slide It is perfect for small spaces because it is so small. It rolls quickly and has less drag. Stairs that can be moved easily and won’t slip are included. The LS 1077 texture is just right for fragile lab tools. It works best with fine craft tools that shape tiny parts. It moves easily in small frames. THK LSP 25125 Linear Ball Slide This LSP 25125 one has a base that is extra wide, which makes it easy to hold on to and fit snugly. It stays stable even when you use complicated push techniques. It gives you a firm grip so you can walk safely. Because of this, the motion is smooth and sure. Its soothing glide can help you get through long, hard jobs that need care and strength. More About The Smooth-Glide Linear Ball Slide What Makes It So Good A light and airy roll. There isn’t much mass. The slide is easy to use and feels good. The design of the railing keeps the trail from getting too overgrown. The ball roll line keeps the motion steady and level. For long periods of time, the glide is gentle. As a result, work stays clean and safe. Names You May Know Also called a linear Linear Ball Slide, a linear ball bearing slide block, a linear ball bearing slide factory, a linear ball bearing slide wholesaler, and a linear ball bearing slide. With these names, you can quickly and easily find the part you need. Item Fit Move LS 25150 Long line Soft roll LS 1077 Tiny room Fast glide LSP 25125 Wide base Firm push FAQs It helps parts move in a soft, clear, and steady line. It uses tiny balls that roll smoothly along a clean path. In labs, shops, test spots, craft rooms, and scan tools. Yes, the body is strong and well-suited for extended workdays. You can trust NOKS INTERNATIONAL TRADE GROUP LIMITED for clean, real, and high-grade parts.

High‑strength wear sleeves help protect the shaft by adding a tough but smooth layer around it. They block dirt, sharp bits, dust, and rust that can accumulate over time. These sleeves help the shaft stay firm and smooth, so it can work for a long time without trouble. They also lower the chance of leaks by providing the seal with a clean surface to press against. The sleeves fit tightly on the shaft and stay in place even when the machine shakes or moves fast. They slide on easily and require minimal force. They work well in hard places with heat, cold, or dirt. They last a long time and require minimal care. Why You Need Strong Wear Sleeves Strong wear sleeves protect the shaft from deep marks that can hurt the seal and cause leaks. They help the shaft stay straight and steady, even when the machine speeds up or slows down. They guard the seal so it can move smoothly without damage. They work well in both dry and wet environments and can withstand heat, cold, dust, and dirt without bending or cracking. They help the tool last longer and make each job run more smoothly and safely. They also help distribute force evenly across the shaft, ensuring that no single spot receives excessive pressure. Advantages Key Uses of Wear Sleeves Sleeves are used in many types of machines, ranging from small shop tools to large factory equipment. They are useful in cars, pumps, fans, farming equipment, and more. They add a clean new surface to worn shafts. They help the seal sit correctly and stop cracks from growing. Use Areas Skf 99821 Wear Sleeves: Safe Fit for All Work The Skf 99821 sleeve gives a tight and smooth cover for both light and challenging jobs. It fits neatly on the shaft and adds a clean surface for the seal. It helps reduce sleeve bearing wear by providing the seal with a smooth surface to move against. It stays strong under pressure and speed and does not break easily. It keeps the seal clean and safe from minor cuts. It is suitable for users who want reliable work with little effort. Why Pick Skf 99821 This sleeve helps cut repair costs by saving damaged shafts. It prevents the need for complete shaft replacement and keeps machines running smoothly. It works well with Seal wear sleeves and many seal types. It features a wide surface that remains strong even in high temperatures and under heavy use. It is a reliable and straightforward choice for workshops. Skf 99822 Wear Sleeves: Best for Mid-Size Shaft Fix The Skf 99822 works well for mid‑size shafts that take medium to high force. It helps stop leaks caused by worn or uneven shaft surfaces. It keeps the shaft smooth and protects it from damage caused by bearing shaft wear sleeve wear, which can be attributed to dirt and prolonged use. It helps the seal rest smoothly, allowing it to last longer. Why Pick Skf 99822 This sleeve lasts through many work cycles and can handle high loads. It fits many machines and remains strong even in high temperatures. It helps resolve problems associated with bearing seal wear and cylinder sleeve issues. It lets users stop leaks without taking the whole machine apart. Skf 99838 Wear Sleeves: Made for Rough Work The SKF 99838 is built for tough jobs that involve heavy weights, intense heat, or sudden shocks. It stays steady in harsh places with flying dirt or rough grit. It protects seals from sharp cuts and stops deep grooves from forming. It slows damage to the shaft and keeps the seal clean. It supports Shaft sleeve and the Seal Sleeve and helps them last longer. Why Pick Skf 99838 This sleeve is a strong choice for heavy‑duty jobs. It stops fast wear and blocks deep marks. It helps seals last longer and keeps them from burning or tearing. It keeps the shaft in good shape for extended use. It is ideal for large machines, plant work, and off‑road equipment. Fast Pick Guide Table Sleeve Model Best Use Gain Skf 99821 Light to mid work Smooth face, long life, clean guard Skf 99822 Mid shaft Strong build, low leak, dust control Skf 99838 Heavy work Heat safe, shock safe, long guard Best Place to Buy High-Strength Wear Sleeves The best place to get genuine parts and fast shipping is NOKS INTERNATIONAL TRADE GROUP LIMITED. They offer competitive prices, secure packaging, high-quality wear sleeves, prompt support, and detailed product information for all sleeve types. The products are the best quality and offer the best performances each time with the best durability. Every time you receive the most friendly and professional service from them. FAQs A wear sleeve is a thin steel cover that protects a shaft from damage, such as cuts, dents, rust, and deep scratches. It also provides the seal with a smooth surface to rest. It prevents damage, rust, leaks, and wear that can make machines stop working. They can last a long time with simple care and can handle tough use. You can buy them from NOKS INTERNATIONAL TRADE GROUP LIMITED, a trusted seller.

When a machine has a smooth drive, it moves without making any noise or bumps. So, even when going very fast, every part stays calm and safe. In this situation, the Cylindrical Roller Bearing is very important. As they move in straight lines, the small, round rollers evenly spread the weight. This keeps all the parts in harmony and quiet. The action isn’t a grind; it’s more like a smooth glide. All the parts work well, and these bearings save energy and keep wear and tear to a minimum. That’s why people all over the world admire them in all kinds of machines, big and small. Working Method of Cylindrical Bearings The cylindrical roller thrust bearings may look simple on the outside, but they are very strong on the inside. Each small roller spins all the time and helps hold up weight. All pictures of cylindrical roller bearings show the shiny metal and smooth, round frame. They are built in a way that lets them move quickly and resist pressure. The way machines are made keeps them from getting too hot or shaking too much. These bearings make even the hardest jobs easy. They make sure that the machine is safe, working, and ready to go at any time. Quadruple Row Cylindrical Roller Bearings The four-row type is not afraid of hard work. These people are the unsung heroes who work in factories that make steel, electricity, and paper. They can carry heavy things without making any noise. The four-row roller design makes it stronger while lowering heat and friction. Here are two popular models: Model Inner (mm) Outer (mm) Width (mm) Weight (kg) E-4R9216 460.000 650.000 470.000 40.000 E-4R9604 480.000 680.000 500.000 640.000 E-4R9604 is made to last a long time and is perfect for big, heavy systems. Both use smart engineering to cut down on heat and friction. With these cylindrical bearing roller types, every movement is smooth, quiet, and lasts a long time. Double Row Cylindrical Roller Bearing The double row cylindrical roller bearing lets one body hold twice as much weight as it could before. It spins well and smoothly while holding its weight on both sides. They are used in engines, gear tools, and cranes. They are huge and have a lot of power. These are two great examples: Model Inner (mm) Outer (mm) Width (mm) Weight (kg) SL04-5030NR 150.000 225.000 100.000 13.600 SL04-5032NR 160.000 240.000 109.000 16.800 The SL04-5030NR stays quiet and works well even when it’s going fast. The SL04-5032NR is the best choice for machines that need to move big things all the time. You can trust these double cylindrical roller bearings because they are strong and long-lasting. They stay stable, don’t break down quickly, and don’t shake. Different Types of Cylindrical Bearings There are many different types of circular roller bearings to meet a wide range of needs. Some deal with linear pressure, while others have to deal with forces that are spinning. The dual-row cylindrical bearings can do both jobs at the same time. Some are sealed so that they can be cleaned, and others are open so that air can flow through them. Most of them are made of strong steel, so they can handle hot or humid conditions. Turbines, industrial tools, and car engines all use them. They make sure that every step is safe and low-key. Main Benefits of Cylindrical Bearings Select the Right Cylindrical Roller Bearing Get the Most advanced Cylindrical Roller Bearings Smooth drive systems require tough, quiet, and reliable components, such as the cylindrical roller thrust bearing and the double-row cylindrical roller bearing. Models like E-4R9216, E-4R9604, SL04-5030NR, and SL04-5032NR give long life and power. They reduce friction, conserve power, and keep machines running like new. For trusted parts and expert help, always visit NOKS INTERNATIONAL TRADE GROUP LIMITED. They bring strength, safety, and smooth motion in every bearing they make. Get the exact quality bearings that are made for the best outcomes every time. Especially designed to complete the heavy duty tasks easily. FAQs What is a cylindrical roller bearing? It’s a bearing with small cylinders that roll smoothly and carry heavy loads with little friction. Why are double row cylindrical roller-bearings special? They can take pressure from both sides while staying light and smooth. How often should I check them? Check, clean, and oil them every few months for safe work. Where can I find good cylindrical roller thrust bearings? You can buy them from NOKS INTERNATIONAL TRADE GROUP LIMITED, known for their fair price and top quality. Can I see how they look? Yes, every cylindrical roller-bearing image is clearly displayed on their website for easy viewing. What kind of machines use them? They are used in engines, mills, cranes, turbines, and large industrial machines that require smooth and steady motion.

Needle roller bearings are small parts that are very strong. They help machines move and work every day. Even though they are small, they can carry a hefty weight. They allow machines to run smoothly and efficiently without stopping. These bearings last a long time. They make machines quiet and save energy. Factories, farms, cars, and big machines all use them. Needle roller-bearing manufacturers make them with care. They ensure that each bearing is strong and functions appropriately. High-performance bearings like these work hard, last long, and keep machines safe. They are made to do heavy work for many years. Our bearing is very strong and durable, and very useful. Heavy-load machines need these high-performance bearings. Needle Roller Bearings for Heavy Load Applications These needle roller bearings are designed to support heavy loads in confined spaces. Inside, they are thin and long. This spreads the load so the bearing does not break. They are low friction bearings, which means machines use less power and stay cool. They are also low noise vibration bearings, so machines run quiet. Many industries, such as construction, agriculture, and aviation, require these strong components. They make machines work better and last longer. Machines with these bearings break less often. They also save money because they do not require frequent repairs. These bearings ensure that work continues without interruption. Benefits of Working with Bearing Manufacturers and Suppliers Working with reputable needle roller bearings manufacturers and suppliers is highly beneficial. They manufacture parts that are strong and durable. They also provide guidance on selecting the appropriate bearings. The McGill Bearing Company manufactures a wide range of bearings. Their McGill bearing catalog displays all the available options. You can find bearings that are strong, quiet, easy to use, and durable. Using trusted suppliers makes sure machines stay safe and work longer. Industries save money because bearings are less likely to break. They also save time because machines do not stop. Good suppliers help industries get the correct bearing for every machine. We are provided with a great price for affordable wholesale. MCGILL GR-88-N: Optimized for Heavy-Duty Applications The MCGILL GR-88-N is a strong and reliable bearing. It is part of the GR-N Bearing Series. It can carry a substantial weight and operate under pressure for an extended period. This bearing is designed for low friction, allowing it to move smoothly and remain cool. It is also a low noise vibration bearing, so it runs quiet. Industries that require durable industrial bearings rely on the GR-88-N. It is used in machines that operate daily and require robust materials. McGill bearing distributors say it is one of the best choices for machines that need long life and strength. This bearing ensures machines continue to operate without interruption. MCGILL GR-56-N: Compact Design, Maximum Efficiency The MCGILL GR-56-N is small but very strong. It fits into machines that have limited space. Even though it is small, it can carry a heavy weight. This bearing is low-friction, allowing machines to move easily and preventing them from overheating. It is also a low-noise, vibration-resistant bearing, allowing it to run quietly. The GR-56-N is designed to withstand prolonged use and perform well in demanding conditions. Industries use it in small machines that need strong, durable parts. High-performance bearings like this save energy, time, and money. Machines operate more efficiently without stopping when this bearing is used. MCGILL GR-96-N: Engineered for High Load Capacity The MCGILL GR-96-N is made for machines that carry hefty loads. It is strong, precise, and very reliable. It is also a low friction bearing, so machines do not waste energy. It is quiet because it features a low-noise vibration bearing. The GR-96-N lasts a long time, so machines do not stop often. It is listed in the McGill bearing catalog for many industries. Companies use it to reduce machine breakdowns and save money. It makes machines more efficient. This bearing is ideal for demanding machines and heavy-duty applications. It helps machines last longer and function more efficiently. MCGILL GR-104-N: Heavy-Duty Performance and Longevity The MCGILL GR-104-N is one of the strongest bearings in the GR-N Bearing Series. It is built to carry the heaviest weight. It is precise, durable, and lasts many years. This bearing is low friction, so machines stay cool and move easy. It is also a low-noise, vibration-resistant bearing, ensuring quiet and safe operation. Industries use it to keep machines working longer. McGill bearing distributors recommend it for machines that run continuously without stopping. The GR-104-N is trusted by factories and heavy machines. It is strong, reliable, and designed for long-lasting use. Why Choose MCGILL Bearings McGill bearings are renowned for their strength and reliability. They last long and work well in challenging conditions. The McGill bearing catalog offers a wide range of options for various machines. These bearings are designed to be low-friction, allowing machines to run smoothly. They are also low noise vibration bearings, so machines run quiet. Extended service life bearings save money because they last longer. The McGill Bearing Company makes sure every bearing is strong and precise. Choosing McGill bearings helps industries save money, keep their machines running smoothly, and avoid potential problems. They make machines safer and more reliable. Applications of Needle Roller Bearings in Industry Needle roller bearings are used in many machines and industries. Cars, trucks, tractors, construction machines, and planes all need them. They carry heavy loads in small spaces. They make machines move smoothly and quietly. Low friction bearings help machines save energy. Low noise vibration bearings make work safer. Extended service life bearings last longer, reducing the need for repairs. Machines with these bearings operate more efficiently, work harder, faster, and last longer. Industries save time and money when they use strong and reliable bearings like these. These bearings enable machines to operate continuously without interruption. Maintaining High-Performance Bearings Taking care of needle roller bearings is very important. Checking them regularly helps keep them working well. Using the right oil or grease helps them last longer. … Read More “High-Performance Needle Roller Bearings for Heavy Loads” »

Durable and long-lasting stainless steel ball bearings are the exact choice for keeping the machine running in a smoothest way. These bearings resist the noise and friction to keep the machine moving accurately. The whole machine needs these small bearings to keep the machine running swiftly. These machines are used in every kind of machine. These are the most essential parts of the machine. To keep the friction away and run the machine smartly these machines are the core elements. There are many types of bearings available for various types of machinery needs. You can get the exact size for your machines by measuring the bearing sizes. There are also customized options available for these bearings. Select Stainless Steel Ball Bearings Stainless Steel Ball Bearings are especially manufactured to resist the rust. These are the best choice for various types of machinery needs. These machines are durable and smooth enough to keep the whole machine running without issues. Main Benefits: These bearings are the best quality choice for every type of vehicle. You can use it easily. Best Quality NTN Ball Bearings When you need bearings you can trust, choose NTN Ball Bearings. They are known for quality and strength. Here are some of the best types they make. NTN Ball Bearings Deep Groove Ball Bearings, NTN Ball Bearings Insert Bearings, NTN Ball Bearings Thrust Ball Bearings, NTN Ball Bearings Megaohm Ball Bearings Deep Groove Ball Bearings If you need fast and smooth movement, NTN Deep Groove Ball Bearings are an excellent choice. They are used in motors, fans, and power tools. Their special shape helps them spin quietly and stay steady even when working hard. Why they’re great: You can find them in many machines because they are quiet and reliable. Insert Bearings Do you need bearings that are easy to install and stay strong? Try NTN Insert Bearings. They are simple to set up and hold tight in machines like conveyors and farm tools. They stay in place even with heavy use. Key benefits : They are ideal for machines that operate continuously for extended periods. Thrust Ball Bearings If your machine moves forward and backward, NTN Thrust Ball Bearings are the ideal solution. They help carry heavy loads and keep motion smooth and gentle. Advantages: They’re ideal for machines that require both power and balance simultaneously. Megaohm Ball Bearings If you use electric tools, NTN Megaohm Ball Bearings are the safe choice. They block electricity and stop damage from power shocks. Best features: They help your machines stay safe and work longer. Different Sizes for Every Need You can find stainless steel ball bearings in various sizes for a wide range of applications. Here are some examples: Size Common Use 1 inch stainless steel ball bearings Big machines and engines 2mm stainless steel ball bearings Watches and small tools Small stainless steel ball bearings Toys, fans, and light machines You can also use stainless steel instrument ball bearings for accurate tools or stainless steel ball bearing swivels for fishing and other flexible parts. Tips for Using Stainless Steel Bearings These steps help your stainless steel bearing balls function more efficiently and last longer. Top Stainless Steel Ball Bearings Manufacturers Finding a reputable stainless steel ball bearings manufacturer is crucial. A trusted name is NOKS INTERNATIONAL TRADE GROUP LIMITED. They make many kinds of ball bearing stainless steel products for all uses. Reasons to Pick: They are renowned for their strong, safe, and long-lasting bearings, which are utilized in numerous industries. FAQs They help fans, cars, tools, and machines move smoothly. No, they resist rust and stay strong in wet places. NTN Ball Bearings are trusted around the world for speed and strength. You can buy them from NOKS INTERNATIONAL TRADE GROUP LIMITED online. Yes, they work great for fishing and outdoor machines.

Machines keep the world working. From trains to tools, every machine needs bearings. Bearings help them move smoothly and safely. A precision bearings distributor connects people with the right parts. They don’t just sell bearings. They give help, care, and advice. They ensure that every bearing fits correctly and lasts a long time. With trusted brands and expert help, they keep machines strong and ready. We are also provided with the best quality precision bearings. And we are Top top-rated precision bearings distributor. They make sure every bearing fits well and lasts long. With trusted brands and expert guidance, they keep machines working strong, safe, and ready for any job. Understanding the Role of a Precision Bearings Distributor A precision bearings distributor is more than a seller. They are a helper and a guide. They work with builders, repair teams, and engineers. They listen to what each customer needs. Then they help find the best fit. A reputable precision bearing company understands the operation of various machines. They are familiar with trains, large machinery, and factory lines. They help save time and make work easier. They keep every system running smoothly. Expertise and Technical Support in Precision Bearings When the wrong bearing is used, the machine stops working. A bright precision ball bearing supplier helps prevent that. They have extensive experience and in-depth knowledge. They help select bearings that last longer and move more smoothly. They also teach how to set them up and care for them. You don’t just buy from them. You get full support and help. That’s why good distributors are trusted partners in every field. The Importance of Industrial Precision Bearings Distributors Big machines need strong bearings. Industrial precision bearings distributors ensure that those bearings are always ready. They supply parts that can take heat, weight, and speed. They serve various industries, including trains, mining, and energy. They work with trusted brands like FAG, TIMKEN, and RBC. These brands mean power and quality. Every bearing is checked before delivery. This keeps customers safe and happy. A good distributor makes sure nothing less than the best leaves their doors. Custom Solutions for Specialized Applications Every job needs something special. A precision bearings manufacturer builds bearings for those special needs. Trains require robust bearings that can withstand prolonged periods of operation. Machines need fast ones that stay cool. Industrial cam follower bearings must operate continuously without failure. Distributors help match each product to each job. They offer custom plans for every need. With these custom options, work becomes easier, safer, and smoother. TIMKEN 795/792CD Double Row Inch Tapered Roller Bearing The TIMKEN 795/792CD Double Row Inch Tapered Roller Bearing is built for strength. It has two rows of rollers for extra power. It can handle heavy loads and side pressure without issue. This double-row tapered roller bearing is compatible with both old and new systems. It is also an inch tapered roller bearing, made for machines using inch sizes. Many industries rely on it for long life and smooth operation. For any precision bearings distributor, this product is a symbol of quality and reliability. FAG F-807551.ZL Single Row Cylindrical Roller Bearing The FAG F-807551.ZL Single Row Cylindrical Roller Bearing is made for speed. It is strong, smooth, and steady. This single row cylindrical roller bearing works well in trains and large machines. It handles heavyweight but stays cool. It is quiet even when working hard. It is simple to install and easy to maintain. Many engineers trust FAG because it always performs well. This bearing helps motors and machines run safely for years. FAG 558320C J20A Cylindrical Roller Railway Bearing The FAG 558320C J20A Cylindrical Roller Railway Bearing is made for trains. It helps them run safely. It is quiet and powerful. This bearing is an Insulated Railway Bearing. It stops electric current from causing damage. It’s used in Cylindrical Roller Bearing Railway systems worldwide. It helps trains move smoothly and lowers repair time. For any precision bearing company, this product is key to safe rail travel. RBC Cam Follower Bearing NOV:30158767-04 The RBC Cam Follower Bearing NOV:30158767-04 is small but tough. It helps machines move with ease. It is used in robots, conveyors, and factory machines. This cam follower bearing handles heavy shock and keeps rolling strong. It is one of the best industrial cam follower bearings in the market. RBC bearings are renowned for their long life and reliability. Distributors trust this one for its smooth motion and simple design. Building Trust Through Quality and Experience A good precision bearings distributor builds trust with care and honesty. They sell only real and tested products. They keep clear records of all orders. Their team stays trained and ready to help. They care about every customer, even after the sale is complete. They give advice and support when needed. Their promise is simple — the correct bearing, every time. This is why people trust them year after year. Precision Bearings for Railway and Industrial Sectors Trains and factories both need good bearings. Railway Bearings, like FAG Railway Bearing and Cylindrical Roller Bearing Railway types handle heat, weight, and weather. Insulated Railway Bearings protect electric trains from damage. In factories, double row tapered roller bearings, single row cylindrical roller bearings, and industrial cam follower bearings keep machines working well. Each one plays a small part in a big job. Together, they ensure systems remain safe and reliable. Why Choose a Precision Bearing Company for Your Needs A good precision bearings distributor helps you find the right part fast. They save you time and money. They know what each bearing does and where it fits best. Whether you need an inch tapered roller bearing, a cylindrical roller bearing, or a cam follower bearing, they have it ready. They offer straightforward advice to help you make informed choices. They work closely with top precision bearing manufacturers to ensure you receive trusted, long-lasting quality. Delivering Value Through Innovation and Reliability A strong precision bearings distributor constantly improves. They utilize innovative tools, … Read More “Precision Bearings Distributor: Tailored Solution, Expertise” »

Sealed needle roller bearings are the exact quality bearings that are suitable for various types of industrial sectors. These are especially designed to pass the heavy loads and bear the high pressures easily. The bearing has an extra advanced part which is the seal that protects the core of the bearing. It prevents the dirt and the harmful elements from getting in. You do not need to take extra care of the bearings. You can use these bearings in many places for industrial machine work. These bearings are manufactured with the materials that are high quality. The high quality materials keep the whole body part secure from breaking. These bearings are the most suitable elements in the machines that are built for the industrial sectors. They resist the friction and let the machine work quickly and quietly. Strong and Smooth Power for Every Machine Every machine has small parts that help it function more efficiently. A crucial component is the sealed needle roller bearing. These small parts make machines run smoothly, quietly, and last longer. They help reduce friction, withstand heavy pressure, and ensure everything works correctly. If you want your machines to run well with less trouble, sealed needle roller bearings are a wise choice. You can buy strong, high-quality ones from NTN, available at NOKS INTERNATIONAL TRADE GROUP LIMITED, a trusted global company known for great products and reliable service. Use Sealed Needle Bearings for Accuracy Machines often operate in harsh environments with dust, heat, and moisture. Sealed needle roller bearings are made to handle those conditions. The seals keep dirt out and grease in, so the bearings stay clean and last longer. The double sealed needle roller bearing adds extra protection, keeping parts safe from wear and tear. That means less maintenance and fewer breakdowns. These bearings are ideal for motors, conveyor belts, and robots that require smooth operation and durability. Accurate Quality Sealed Needle Bearings NTN Needle Roller Bearings Thrust Bearings When machines carry heavy loads, they require bearings that can withstand high pressure. NTN Needle Roller Bearings Thrust Bearings are made for that. They are small but mighty and work well in tight spaces. They are used in gearboxes, pumps, and presses. These bearings help keep everything steady and moving smoothly, even under heavy force. Key Features: NOKS INTERNATIONAL TRADE GROUP LIMITED has trusted NTN bearings ready for your machines. NTN Needle Roller Bearings Complex Bearings The NTN Needle Roller Bearings Complex Bearings can handle different types of pressure at the same time. They can manage both sides and push loads, keeping machines balanced. These bearings are ideal for engines, power tools, and other systems that require both strength and smooth operation. The built-in seals help them last longer and reduce the need for repairs. Benefits: For strong and easy-to-use bearings, trust NOKS INTERNATIONAL TRADE GROUP LIMITED, a leading sealed needle roller bearings supplier offering genuine NTN products. NTN Needle Roller Bearings Drawn Cup Needle Roller Bearing If you need a light but strong bearing, the sealed drawn cup needle roller bearings are the best option. These have a thin outer shell that saves space and weight. Even though they are small, they can handle a lot of hard work. They are used in cars, farming tools, and small machines that need fast and reliable motion. Uses: Advantages: These bearings are an excellent choice for anyone looking for wholesale sealed needle roller bearings that last long and work well. NTN Needle Roller Bearings Cam Followers NTN Needle Roller Bearings Cam Followers are used for smooth and controlled motion. They help guide movement in machines like conveyors and robots. The seals protect the inside from dust and keep grease in place. They are built to last and keep running quietly for a long time. Highlights: Get your NTN Cam Followers from NOKS INTERNATIONAL TRADE GROUP LIMITED, a trusted sealed needle roller bearings factory that delivers quality worldwide. Sealed Needle Bearings with Features & Uses Bearing Type Best Use Key Features Thrust Bearings Heavy loads Small, strong, and long-lasting Complex Bearings Mixed forces Two-in-one design, quiet and smooth Drawn Cup Bearings Small spaces Light, strong, and affordable Cam Followers Smooth motion Clean, quiet, and steady movement Exact Place to Purchase Sealed Needle Bearings NOKS INTERNATIONAL TRADE GROUP LIMITED is a trusted name among sealed needle roller bearings suppliers. They sell only tested, high-quality bearings that meet global standards. Their NTN products are reliable, smooth, and safe. These bearings are used in various industries, including automotive, agriculture, construction, and manufacturing. Every bearing is thoroughly inspected for quality and designed to withstand the rigors of tough environments. Whether you need sealed needle roller bearing, sealed drawn cup needle roller bearings, or double sealed needle roller bearing, NOKS has the right one for you. Reasons to Select NOKS: Choosing sealed needle bearings helps machines operate more efficiently and last longer. NTN bearings are trusted for their strength and smooth motion. When you buy from NOKS INTERNATIONAL TRADE GROUP LIMITED, you get genuine products, excellent service, and expert help FAQs They keep grease inside and block dirt and water, which helps machines run better and last longer. Yes! NOKS INTERNATIONAL TRADE GROUP LIMITED sells wholesale sealed needle roller bearings for big and small orders at reasonable prices. Yes, they fit easily without the need for special tools and are simple to replace. No. The seals keep the grease inside, so they need very little maintenance. From NOKS INTERNATIONAL TRADE GROUP LIMITED, a top sealed needle bearings supplier that sells original NTN bearings all over the world.

Machines have numerous small parts, but some are more crucial than others. High precision bearings are tiny parts that make a significant difference. They help things move smoothly and keep parts from rubbing too much. This enables machines to work more efficiently and last longer. These bearings can withstand pressure, heat, and prolonged use. They keep every part in place and help it move the right way. With strong design and steady action, they make sure your machines work well every day, even when the job is tough. High Precision Bearings for Better Machine Performance Precision means being very exact. In factories, cars, planes, and even hospitals, machines need to move smoothly and quietly. That’s where high precision bearings help. These tiny parts make a significant difference they reduce friction, help things spin faster, and keep machines running longer. At NOKS International Trade Group Limited, top design and excellent quality come together to make bearings that keep machines strong and safe. Essential Sides of High Precision Bearings High precision bearings are like the heart of a machine. They allow parts to move without shaking or overheating. These bearings are carefully made to ensure everything stays in place, even under pressure or high speeds. Why They Matter Common Uses Industry Use Aerospace Jet engines, plane landing systems Medical Scanners, surgical tools, dental drills Automotive Gearboxes, turbo systems, wheels Industrial Robots, CNC machines, assembly tools Without bearings, machines would stop or break down quickly. They make movement clean, safe, and steady. First-Rate High Precision Bearings Available SKF S71919 ACD/P4A Super precision Bearing The SKF S71919 ACD/P4A Super precision bearing is known for being fast and accurate. It’s designed for machines that require smooth and steady spinning at extremely high speeds. This bearing helps keep motion clean, quiet, and strong. Key Features Tip: Buy from NOKS International Trade Group Limited to ensure you receive the genuine SKF product. Their experts can help you pick and fit the correct part. TIMKEN 18204X/18335X Single Row Tapered Roller Bearings The TIMKEN 18204X/18335X is strong and reliable. It’s made for heavy machines that need both power and precision. It handles big loads easily and keeps turning without trouble. Benefits Best for: Trucks, large engines, and machines that operate continuously. It maintains high performance even under pressure. TIMKEN 56425/56650 Bearing,Single row tapered roller bearing The TIMKEN 56425/56650 Bearing is built for hard work. It remains smooth and silent, even when used for extended periods or in high temperatures. It is trusted for strong and lasting motion. Highlights Advice: Always purchase from NOKS International Trade Group Limited to obtain genuine TIMKEN parts that function flawlessly and last long. RBC CAM FOLLOWER BEARING, NOV:30158767-04 The RBC Cam Follower Bearing is small but powerful. It helps parts move straight and true. It’s perfect for robots, printers, and other machines that perform the same motion repeatedly. Unique Advantages Although it’s small, it enables machines to operate smoothly and steadily for an extended period. How to Pick the Right Bearing Selecting the right high precision bearings can improve machine performance, increase longevity, and reduce issues. You need to consider speed, size, and the type of job the bearing will perform. Quick Tips Good choices today prevent big problems tomorrow. NOKS can help you find the right fit. Buy from NOKS International Trade Group Limited NOKS International Trade Group Limited is a trusted entity worldwide. They sell genuine, high-quality bearings from reputable brands like SKF, Timken, and RBC. They care about giving you good service and honest products. What Makes NOKS the Best When you choose NOKS, you choose a company that truly understands how your machines work and what they need. Quality high precision bearings help your machines run more efficiently and stay in good condition. If you want less noise, less damage, and more power, choose these bearings. They work hard and last long. They keep everything moving smoothly and make your business more reliable. Every turn matters, and these bearings make each one count. FAQs It means the bearing is made with minimal errors, so it spins smoothly and accurately. Yes! High precision medical device bearings are used in scanners and surgical tools where accuracy is super important. High precision ceramic bearings are lighter, faster, and better at handling heat. Yes. NOKS International Trade Group Limited can find or manufacture the right size and type to meet your needs. With cleaning and oiling, high precision bearings can work for many years, even in demanding jobs.

Durable hydraulic seals keep the lubricant fluid inside and resist the dirt to enter the water. It protects the essential parts of the machines and ensures that it is leak free. The seals are made from the most flexible and durable materials which makes it so strong and easy to use. You can operate the machine easily with these seals. These bearings are especially designed to prevent the sudden breakdown. For its flexibility you can use them in many hydraulic systems for better usability. These seals are especially designed for hydraulic machines. These seals are designed to keep the machine in a great position and prevent costly replacements. Hydraulic Cylinder Seals and Its Usabilities Hydraulic cylinder seals stop oil and other fluids from leaking out of a hydraulic system. They also keep dust, dirt, and water from entering. You can find these durable hydraulic seals in machines like tractors, cranes, forklifts, and construction equipment. The durable hydraulic seals help parts move quietly and smoothly, allowing the machine to maintain its power. When seals wear out or break, the system can lose pressure or stop working correctly. Checking and changing seals on time helps prevent big and costly problems later. Beneficial Sites: Types of Hydraulic Cylinder Seals There are several types of durable hydraulic seals, each with a specific function. They all work together to keep the system sealed and strong. Seal Type What It Does Common Use Rod Seals Stop oil from leaking around the rod Excavators, loaders, presses Buffer Seals Handle pressure and shock Heavy-duty equipment Piston Seals Control fluid pressure inside the cylinder Pumps, cranes Wiper Seals Keep dust and dirt out Outdoor tools Outdoor tools Guide Rings Keep metal parts from rubbing Industrial machines Each type plays a crucial role in maintaining the system’s cleanliness, safety, and optimal functioning. Top-grade SKF Seals Hydraulic Seals Guide rings: Keep Parts Aligned It keeps the Guide rings in the right position. It prevents the metal from getting rubbed and resists the friction. The system runs quietly and quickly with these bearings. It is also used to keep the vibration away and make the bearing long lasting. Benefits: Rod and buffer seals: Hold Pressure and Prevent Leaks It keeps the fluid inside the bearings. It can handle pressure and heavy work easily. Rod and buffer seals help the machine’s essential parts to last long. In the high pressure these seals keep the oil inside and help the metals to easily roll. It also absorbs the high pressure to keep the metal safe. Tips: Piston seals: Power and Control Piston seals keep pressure balanced inside the cylinder. They separate the fluid in the upper and lower parts of the chamber, allowing the piston to move with power and control. Good piston seals make machines firmer, smoother, and more efficient. Key Features: Pro Tip: Use a hydraulic piston seal installation tool to install seals without damage. Always clean the parts thoroughly before installation to achieve the best results. Wiper seals: Keep It Clean Wiper seals clean the rod every time it moves in and out of the cylinder. They wipe off dirt, dust, and water to keep the system clean. Without wiper seals, dirt can get inside and cause leaks or wear. Advantages: Good wiper seals are a must for outdoor or dirty work areas. They protect your machine and help it run better for years. How to Replace a Hydraulic Cylinder Seal Replacing durable hydraulic seals is simple if you use care and the right tools. Here’s how to replace a hydraulic cylinder seal safely. Steps: Pro Tip: Always use complete hydraulic cylinder seal kits or hydraulic square ring seal kits for a perfect fit. Follow your machine’s guide for size and seal type. Best Place for Buying Hydraulic Seals If you want strong, long-lasting hydraulic seal kits, go with NOKS INTERNATIONAL TRADE GROUP LIMITED. They make high-quality durable hydraulic seals that handle pressure, heat, and wear. NOKS durable hydraulic seals are designed for a wide range of hydraulic equipment, from small tools to large construction machines. Why NOKS: NOKS products are trusted worldwide. Visit NOKS INTERNATIONAL TRADE GROUP LIMITED to find the best hydraulic seal kit for your machine. Keep your machines robust, smooth, and reliable with top-quality hydraulic cylinder seal kits from NOKS INTERNATIONAL TRADE GROUP LIMITED. Strong durable hydraulic seals protect your equipment, helping it work like new. FAQs You’ll need hydraulic cylinder seal tools, a hydraulic piston seal installation tool, and a clean cloth. Check every six months. Replace seals if they leak, crack, or wear down. Yes. You can get custom hydraulic seals made for special machines. Yes. NOKS makes hydraulic cylinder seal kits for many brands and models. Old or broken seals can cause leaks and pressure loss. Replacing them keeps your machine safe and in good working condition.